This week I’m tweaking hardware and software on the Acorn CNC retrofit of our DynaMyte 2800 milling machine. I wire up the automatic lubrication pump and fire it up. The automatic cycling lubricator pumps oil through the metering valves that we updated back in October.

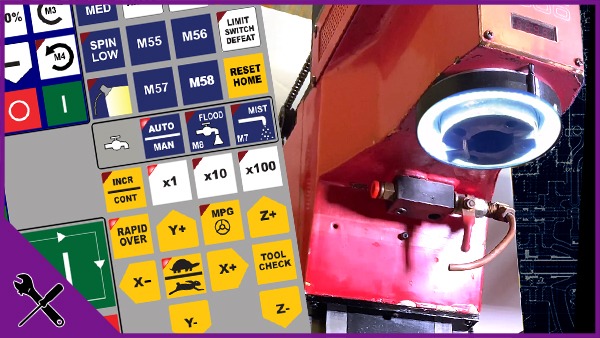

Next I take advantage of the latest update to the Centroid CNC12 software. This version update enables customization of the Virtual Control Panel (VCP) layout such as moving and resizing buttons and programming of custom functions.

Then I spend some time designing a custom light for the spindle. I create a custom 3-D printed housing to position an automotive “Angel Eye” LED ring light to illuminate the table of the milling machine.

Finally, I modify the Acorn PLC code to compensate for a fault condition with the DMM servo motor tuning. I demonstrate the process for compiling custom PLC code for the Acorn and discuss some of the pitfalls.

A little bit of everything to improve the functionality of the machine.